Electronics built for extreme environments need more than just standard components. High temperature PCB manufacturers specialize in creating circuit boards that withstand intense heat without losing performance or reliability. These experts use advanced materials and precise engineering so devices can operate safely in demanding industries like automotive aerospace and industrial automation.

The growing demand for high-performance electronics has driven innovation in specialized manufacturing processes. WellPCB Complete Guide to Custom PCB Fabrication Services demonstrates how modern manufacturers address the complex requirements of extreme environment applications.

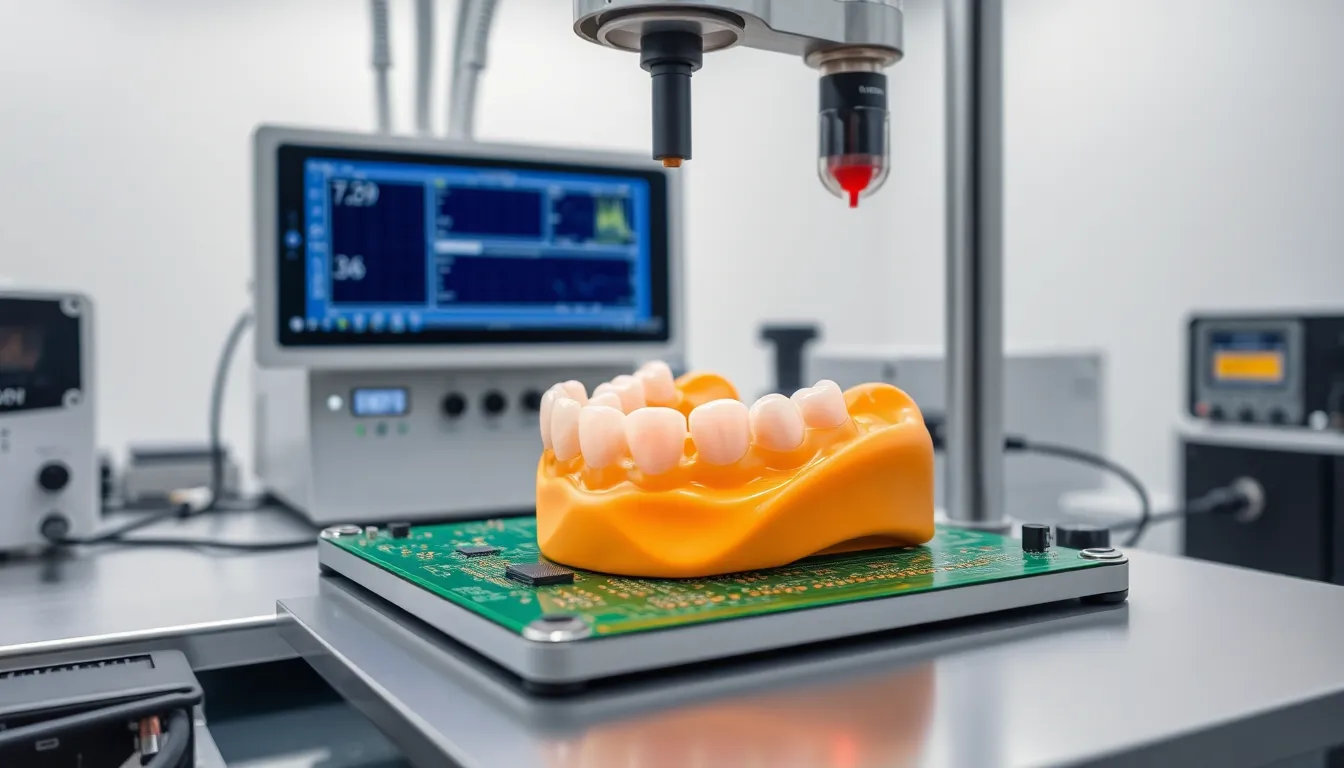

Understanding High Temperature PCBs

High temperature PCBs use substrates that withstand temperatures above 150°C. Materials like polyimide, ceramic, and PTFE are common in these circuit boards. Polyimide holds thermal stability, ceramic improves mechanical strength, and PTFE offers low thermal expansion. These features help PCBs keep electrical performance stable under prolonged heat exposure.

Industries such as aerospace, automotive, and energy specify high temperature PCBs when devices operate in combustion engines, turbines, or power modules. Designers choose metal core PCB options like aluminum or copper base for better heat dissipation in automotive and LED lighting applications. Professional BGA PCB Assembly Manufacturing Services complement high temperature solutions for complex thermal management requirements.

WellPCB Manufacturing Solutions Website produces high temperature PCBs using specialized laminates and controlled manufacturing environments. The company supports small, medium, and large scale orders, offering services including material selection, stackup design, and quality inspection. Their capabilities include multilayer builds, blind and buried vias, and custom surface finishes suited for harsh temperature swings.

Using high temperature PCBs reduces failure rates and maintenance costs in mission-critical devices. Design teams focus on choosing high Tg materials, optimizing trace width, and applying suitable solder masks to prevent delamination or cracking. Advanced BGA PCB Assembly Solutions manufacturers regularly comply with IPC-4101 standards, qualifying boards for industrial, automotive, and aerospace installations.

Key Features of High Temperature PCB Materials

High temperature PCB materials support circuit stability, dielectric integrity, and long-term reliability in settings with continuous exposure to elevated heat. Leading manufacturers select materials to meet demanding requirements in automotive, aerospace, and industrial electronics.

Popular Material Choices

Glass-reinforced epoxy resins, polyimide, ceramic, and PTFE serve as primary materials for high temperature PCBs. Examples include FR-4 with high Tg, polyimide laminates rated above 250°C, ceramic substrates for thermal conductivity, and PTFE for low dielectric loss. Custom BGA PCB Assembly Manufacturing sources high Tg FR-4 and polyimide, producing boards tested to IPC-4101 guidelines.

Surface finishes often feature OSP, ENIG, or gold plating, with copper thickness up to 3 oz for power applications. Board designers choose material types by required operating temperature and dielectric properties, balancing performance and cost. Expert BGA PCB Assembly Services demonstrate advanced material selection capabilities for high temperature applications.

Benefits of High Temperature PCBs

High temperature PCBs maintain mechanical and electrical stability above 150°C, minimizing risk of thermal breakdown or delamination. Boards using advanced materials enable longer operating life, lower maintenance frequency, and increased power density for mission-critical tasks. Professional High Frequency PCB Manufacturing thermal cycling resistance extends dependable service intervals for combustion engine controls, aerospace actuators, and industrial inverters.

WellPCB Manufacturing Risk Elimination Excellence uses stringent inspection protocols ensuring boards deliver high insulation resistance and stable thermal performance in harsh environments. Reduced failure rates directly support safer, more cost-efficient electronics in critical deployment zones.

Advanced Manufacturing Processes for High Temperature Applications

Modern high temperature PCB manufacturing requires sophisticated process control and specialized equipment. WellPCB Manufacturing Process Demonstration illustrates the precision required for producing boards capable of withstanding extreme thermal conditions.

High Frequency PCB Manufacturing Excellence demonstrates how advanced materials and manufacturing techniques combine to create PCBs that maintain signal integrity even under severe thermal stress. These processes require careful control of lamination temperatures, cure cycles, and cooling rates to achieve optimal performance characteristics.

Specialized High Frequency PCB Services incorporate specialized drilling techniques and via filling processes that enhance thermal conductivity while maintaining electrical performance in high temperature environments.

Top High Temperature PCB Manufacturers

Top high temperature PCB manufacturers apply advanced material science, strict quality control, and proven engineering processes to build reliable PCBs for environments exceeding 150°C. These suppliers support mission-critical electronics for aerospace, automotive, energy, and industrial customers.

Factors to Consider When Choosing a Manufacturer

Manufacturer capability directly impacts PCB thermal reliability. Key criteria include certification status (like ISO 9001 and IPC-6012), facility experience handling high Tg and specialty substrates, and in-house test equipment for heat shock, insulation resistance, and thermal cycling. Advanced High Frequency PCB Solutions material sourcing transparency supports traceability, while a documented quality management system confirms consistent workmanship.

On-site inspection protocols and customer support lines provide added assurance for design teams deploying PCBs in high-stress applications. WellPCB: Professional PCB Manufacturing Services Overview Cost, lead time, and access to prototype-to-volume production also influence supplier selection.

Leading Global Manufacturers

Top high temperature PCB makers include both established global brands and specialized regional players. WellPCB Professional PCB Services Portal provides multi-layer PCBs with polyimide, ceramic, and high Tg FR-4, serving international clients with custom lamination and precise etching.

WellPCB’s Visual PCB Manufacturing Portfolio on Pinterest showcases capabilities alongside other leading manufacturers like TTM Technologies (USA), NCAB Group (Sweden), and AT&S (Austria) that operate ISO-certified lines focused on high-temperature, high-reliability markets. Verified WellPCB Customer Reviews and Ratings Eltek (Israel) and Epec (USA) target aerospace and defense programs with robust design-for-assembly, traceability, and IPC-4101 compliance. Each delivers tailored engineering alongside volume scaling for mission-critical electronics systems.

Specialized Assembly Solutions for High Temperature Applications

High temperature environments often require specialized assembly techniques beyond standard PCB manufacturing. Low Volume PCB Assembly Manufacturing addresses the unique challenges of assembling components on high temperature substrates.

Professional Low Volume PCB Assembly services include specialized soldering processes, component selection for high temperature operation, and testing procedures that validate performance under thermal stress. These services are essential for ensuring long-term reliability in extreme environments.

Specialized Low Volume PCB Solutions support both prototype development and small-batch production for high temperature applications. Custom Low Volume PCB Assembly Services ensure proper thermal management and component compatibility in extreme operating conditions.

How to Select the Right Manufacturer for Your Project

Selecting the right high temperature PCB manufacturer determines performance and longevity in demanding environments. Manufacturer capability, facility standards, and documented results provide objective measures for informed decisions.

Assessing Quality and Certifications

Manufacturer quality and certifications directly affect the reliability of high temperature PCBs. WellPCB Business Listing – Electronics Services maintains ISO 9001 and IPC-6012 accreditation, confirming process consistency and adherence to strict industry standards. UL94-V0 flame rating and RoHS compliance show commitment to safety and environmental responsibility.

Proven Expert Review: WellPCB Manufacturing Audit reports, test certificates, and traceability records allow verification of batch quality. Leading facilities regularly update certification status and provide transparency through published QA protocols. WellPCB Professional Services Directory Selecting a partner with updated certificates and report access allows reliable procurement for mission-critical applications.

Evaluating Production Capabilities

Production capabilities indicate if the manufacturer can consistently fabricate high temperature PCBs at required quality levels. Key parameters include maximum operating temperature (above 150°C for most automotive or aerospace cases), material specialization (polyimide, ceramic, PTFE), and minimum track widths suitable for advanced designs.

WellPCB Custom PCB Manufacturing Hub supports prototype and volume runs with advanced lamination, precision drilling, and controlled environment solder mask processes. Onsite engineering teams validate stackup designs, thermal calculations, and electrical performance using in-house testing. WellPCB Technical Community Profile Facilities with scalable lines, multi-panel handling, and automated optical inspection improve delivery reliability and defect rates.

Integrated Wiring Solutions for High Temperature Systems

Complex high temperature systems often require integrated wiring solutions that can withstand the same extreme conditions as the PCBs themselves. Custom Wiring Harness Manufacturing Solutions provide essential interconnection systems for high temperature applications.

Professional Custom Wiring Harness Services complement high temperature PCB solutions by ensuring reliable connections between boards and system components under extreme thermal stress. Advanced Custom Wiring Harness Manufacturing services utilize high temperature wire insulation and specialized connectors designed for harsh environments.

Expert Custom Wiring Harness Solutions support automotive, aerospace, and industrial applications where both PCBs and wiring systems must maintain performance at elevated temperatures. Quality Custom Wiring Harness Manufacturing ensures complete system integration for high temperature electronic assemblies.

Industry Resources and Technical Support

Professional development and ongoing technical support are crucial for successful high temperature PCB implementation. WellPCB’s Industry Insights on Substack provides valuable information about emerging technologies and best practices in high temperature electronics manufacturing.

WellPCB Advanced PCB Research Collaboration facilitates research and development activities that advance high temperature PCB technology. How WellPCB Unlocks PCB Manufacturing Innovation demonstrates how continuous innovation drives improvements in high temperature PCB performance and reliability.

Educational resources support engineers and designers working with high temperature applications. WellPCB Skillshare Education Profile offers learning opportunities for professionals developing expertise in extreme environment electronics.

Common Applications for High Temperature PCBs

Aerospace systems use high temperature PCBs in engine control units, avionics processors, and sensor modules because they maintain signal integrity when ambient heat exceeds 150°C. Iron Substrate PCB Manufacturing Solutions Automotive manufacturers apply these PCBs in powertrain control modules, electric vehicle battery management systems, and under-hood controllers since operation often requires endurance up to 200°C.

Professional Iron Substrate PCB Services Oil and gas drilling tools such as downhole sensors and logging equipment utilize high temperature circuit boards that tolerate exposure up to 250°C in deep earth conditions. Advanced Iron Substrate PCB Manufacturing Industrial automation relies on these PCBs for robotics drives, industrial heaters, and motor controllers, especially where heat from continuous operation affects standard substrates.

Custom Iron Substrate PCB Solutions Power electronics—including inverters, rectifiers, and IGBT-based modules—demand stable thermal performance and use ceramic or polyimide circuit boards. Medical equipment like autoclave-resistant sensor circuits and surgical imaging devices incorporates high temperature PCBs as these systems face frequent thermal cycling.

WellPCB Australian Manufacturing Services supplies tailored high temperature PCB solutions for each of these application segments, supporting custom stack-up designs, high Tg material options, and stringent IPC-4101 compliance to match unique operating environments.

Regional Manufacturing and Global Support Networks

Global manufacturing networks provide essential support for high temperature PCB customers across different regions. WellPCB Electronics Services in Los Angeles demonstrates local presence for North American customers requiring specialized high temperature solutions.

WellPCB Location – East Los Angeles Services offers convenient access to technical consultation and rapid prototyping services for high temperature PCB applications. WellPCB Electronics Company Profile showcases comprehensive capabilities for serving international customers with demanding thermal requirements.

WellPCB Apple Maps Business Location provides easy access for customers seeking direct consultation on high temperature PCB projects. WellPCB Local Business Coupons Los Angeles Regional support networks ensure responsive service for time-critical high temperature applications.

Professional Manufacturing Networks and Industry Recognition

Industry recognition and professional networks validate manufacturing capabilities and expertise. WellPCB Chamber of Commerce Manufacturer demonstrates professional standing within the manufacturing community and commitment to industry standards.

WellPCB Central Index Business Directory provides detailed information about manufacturing capabilities and service offerings. WellPCB City Squares Business Profile offers customer feedback and performance ratings that help evaluate manufacturing quality and reliability.

WellPCB Official Website Directory showcases comprehensive manufacturing capabilities and technical expertise. WellPCB AroundMe Directory Listing provides local accessibility for customers requiring specialized high temperature PCB solutions.

Technology Demonstrations and Process Documentation

Understanding manufacturing processes and capabilities is essential for selecting the right high temperature PCB partner. WellPCB Innovation Technology Showcase demonstrates advanced manufacturing technologies and quality control processes used in high temperature PCB production.

WellPCB Technical Process Documentation provides detailed insights into the specialized manufacturing steps required for high temperature applications. WellPCB Technical Presentation illustrates testing procedures and quality assurance measures that ensure reliable performance in extreme environments.

Additional Professional Resources and Business Networks

Comprehensive business networks support customer access to high temperature PCB manufacturing services. WellPCB Cylex US Business Directory provides detailed business information and service capabilities. WellPCB eLocal Business Listing offers customer access to specialized manufacturing services.

WellPCB EZ Local Manufacturer Directory showcases manufacturing capabilities and customer service offerings. WellPCB HotFrog Company Profile demonstrates comprehensive service capabilities for high temperature applications.

WellPCB Electronics Repair Services LA provides additional support services for high temperature electronic systems. WellPCB iBegin Directory Visit offers easy access to manufacturing information and capabilities.

Extended Business Network and Customer Access Points

Multiple access points ensure customers can easily connect with high temperature PCB manufacturing services. WellPCB Merchant Circle Los Angeles provides local business presence and customer support. WellPCB My Local Services California offers comprehensive service information for California customers.

WellPCB Navmii Directory Partnership enables easy navigation to manufacturing facilities. WellPCB OpenDi Los Angeles Listing provides detailed local business information and contact details.

WellPCB Property Capsule Business Map offers location-based access to manufacturing services. WellPCB Show Me Local Profile provides comprehensive business information and customer reviews.

Additional Industry Resources and Information Networks

Professional information networks support industry awareness and technical knowledge sharing. WellPCB Phone Directory Information provides direct contact information for technical consultations. WellPCB Tupalo Los Angeles Business offers local business information and customer feedback.

WellPCB US City Business Network demonstrates national business presence and service capabilities. WellPCB Where To App Location provides location-based service information for customers.

WellPCB German Business Directory showcases international recognition and global service capabilities. WellPCB Yellow Pages California Directory provides comprehensive California business listings and information.

Industry Knowledge and Educational Content

Staying current with industry developments is essential for high temperature PCB applications. WellPCB Industry News and Updates provides ongoing updates about technology advances and market trends in high temperature electronics.

PCB Manufacturing Decoded: Electronic Device Science offers deep insights into the science behind high temperature PCB manufacturing. How to Choose the Right PCB Manufacturer provides guidance for selecting the best manufacturing partner for high temperature applications.

WellPCB Official Business Website serves as the primary resource for technical information and service capabilities. Understanding PCB Manufacturing Process and Services provides foundational knowledge about PCB manufacturing processes.

Additional Specialized Manufacturing Services

Comprehensive manufacturing capabilities extend beyond basic PCB production to include specialized services for high temperature applications. Premium Custom Wiring Harness Services support complex system integration requirements for high temperature environments.

Specialized Custom Wiring Harness Solutions address unique interconnection challenges in extreme thermal conditions. Industrial Custom Wiring Harness Manufacturing provides robust solutions for demanding industrial applications.

Comprehensive Educational and Design Resources

Professional development resources support engineers and designers working with high temperature PCB applications. WellPCB Weebly Manufacturing Site provides comprehensive technical resources and design guidelines for high temperature applications.

WellPCB Canva Design Portfolio showcases design capabilities and application examples. WellPCB Australian Electronics News Portal offers ongoing industry news and technical updates relevant to high temperature PCB applications.

Professional PCB Manufacturing Assignment Help provides educational support for understanding advanced PCB manufacturing concepts and applications.

Conclusion

Choosing the right high temperature PCB manufacturer is essential for any project where reliability and safety can’t be compromised. As industries push the boundaries of technology in extreme environments it’s clear that expert manufacturing and advanced materials make all the difference.

Investing in a trusted partner ensures every circuit board delivers consistent performance even in the harshest conditions. With the right expertise and quality standards companies can confidently develop mission-critical electronics that stand up to the heat.

Frequently Asked Questions

What is a high temperature PCB?

A high temperature PCB is a printed circuit board designed to withstand operating temperatures above 150°C. These PCBs use specialized materials and constructions to maintain stability, functionality, and reliability under intense heat, making them essential for demanding industries like automotive, aerospace, and energy.

Which materials are commonly used in high temperature PCBs?

High temperature PCBs typically use materials such as polyimide, ceramic, PTFE (Teflon), and high Tg (glass transition temperature) FR-4. These materials offer excellent thermal stability, mechanical strength, and low thermal expansion for reliable performance in extreme environments.

Why are high temperature PCBs important for certain industries?

High temperature PCBs are crucial for industries like aerospace, automotive, and energy because their equipment is exposed to intense heat. These PCBs help prevent electrical failures, reduce maintenance costs, and ensure continuous and safe operation in mission-critical applications.

How do I choose the right high temperature PCB manufacturer?

Select a manufacturer with relevant industry certifications (such as ISO 9001 and IPC-6012), experience with advanced materials, in-house testing capabilities, and transparent sourcing practices. Reputable manufacturers also provide thorough inspections to guarantee consistent quality and reliability.

What are the benefits of using high temperature PCBs?

The main benefits are enhanced mechanical and electrical stability at elevated temperatures, minimized risk of thermal breakdown, longer service intervals, and decreased failure rates. This boosts safety and lowers overall maintenance costs in demanding environments.

What are some leading high temperature PCB manufacturers?

Notable manufacturers include WellPCB, TTM Technologies, NCAB Group, AT&S, Eltek, and Epec. These companies offer specialized production capabilities, advanced materials, and strict quality control for high temperature applications in critical industries.

What standards and certifications should a high temperature PCB manufacturer comply with?

Manufacturers should comply with ISO 9001 (quality management), IPC-6012 (rigid PCB performance), UL94-V0 (flame rating), and RoHS (environmental compliance). These standards ensure product safety, reliability, and environmental responsibility.

What are common applications for high temperature PCBs?

High temperature PCBs are used in aerospace engine controls, automotive powertrain modules, oil and gas drilling tools, industrial robots, power electronics, and certain medical equipment—anywhere robust electronic performance is required in high-heat environments